Combined Heat & Power / Co - Generation

Project:

2

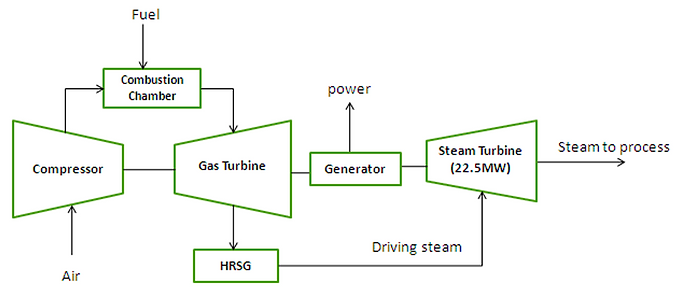

Integration of a Gas Turbine with an Ammonia Process for Improving Energy Efficiency

Publisher:

Applied Thermal Engineering, Vol. 58, Issues 1-2, pp. 594-604, September 2013

Abstract

This paper is intended to investigate how one can improve the overall energy efficiency of an ammonia process. A gas turbine is integrated with the process to reduce the exergy loss associated with ammonia synthesis loop and produce electricity. Combined Pinch and Exergy Analysis is applied to identify how exergy loss is distributed throughout heat transfer process. This is needed to find appropriate placement for gas turbine integration. Having introduced an exergy loss index for the whole plant, including the heat transfer process and gas turbine system, optimum shaft-work can be generated through recovering part of the exergy loss. Eventually, heat integration of the process streams is done to reduce additional consumption of high pressure steam caused by temperature drop in gas turbine. The results show that 4 MW of electricity can be produced in exchange of adding 7350 kW of high pressure steam. Total amount of exergy loss is reduced by 3323 kW, which indicates 19% reduction compared to the existing process. Based on the economic data, the net income is estimated to be 2,549,653 US$/y with 3 years payback.